' cold roll that i weld about 6" on top of the king pin and then with a jack under the axle beam supporting some weight use a big hammer on top of the cold roll. Alot of the times the pin will fall out with a small hammer. Now the spindle is out of the way.Let it cool and then grind off smooth the top of the king pin. Then lift the spindle up and cut the king pin above the axle beam under the spindle. Then with it out of the way cut the king pin and cut about 1/2" out of it.

Mack king pins how to#

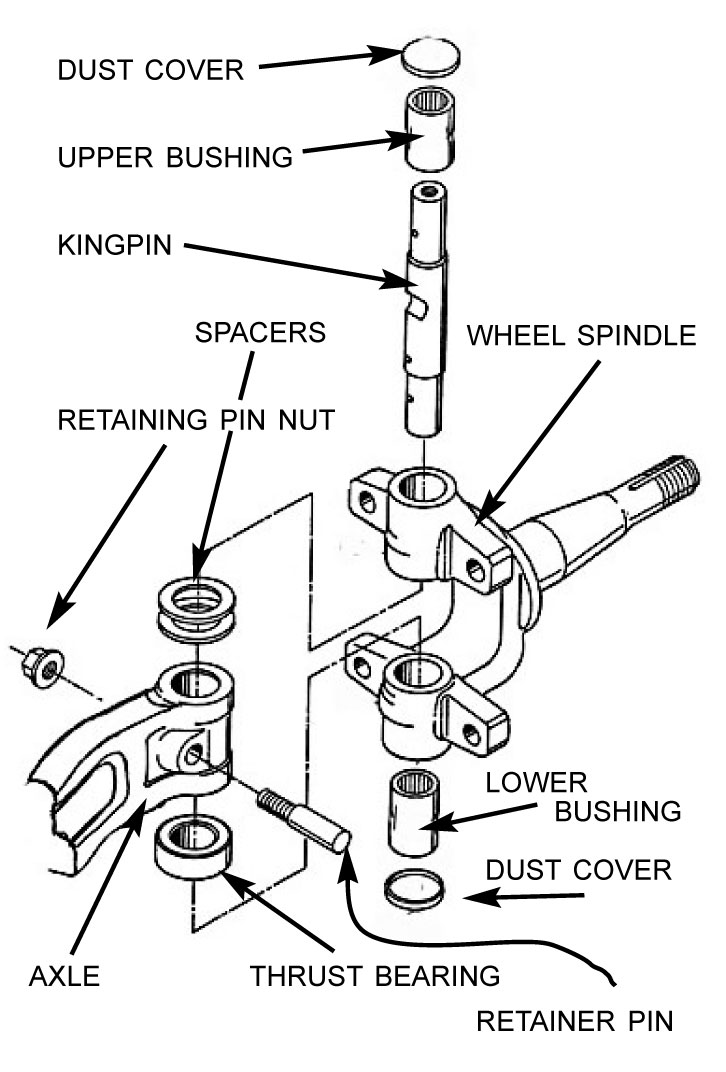

Let me tell you how to remove them with out heating the axle beam and i have did many this way.With a torch cut the thrust brg out from under the axle beam were it set on top of the spindle. Duie Pyle tractor I think that the boss bought.

Had to heat that one up with a rosebud and swing an 10-Lb Persuader Wrench on and off for the better part of 1/2 hour to 45 mins. It sure makes you think when you're trying to avoid the bumps on the Cross Bronx Expressway!! The only thing about it is if you think of how small that button bearing is and if you have ever seen one break. That's really a pretty great record and I can't deny it. I've only seen this thrust button break on one truck in the past and remember there being a recall back in '85 to take them apart and replace the bearings. On the Mack style all the weight of the truck is sitting on a very small, by comparison, thrust button style bearing in the knuckle and resting on the bottom of the pin. The pin only has one job to do, the one it's supposed to do, keep the knuckle in alignment with the axle and allow it to pivot. It's positioned between the the bottom of the axle beam and the top of the lower steering knuckle bushing bore-you have a much larger bearing surface. Was a large straight pin (top and bottom bushings were the same size) tapered pins the top bushing is always smaller.Īlso with this arrangement there is a much larger thrust bearing to support the weight of the truck and it's positioned in a place that makes much more sense We used to have Rockwell front axles in our Brockways never gave us much problems. With a straight pin like you have is I think a better set up than the Mack tapered pin anyway. Please see below for specific Product(s) warranty periods and details.ĮSCO warrants to its customers that bolts, machined components, or threaded areas inside of the Product(s) or outside of the Product(s) will not fail as a direct result of and caused solely due to defects in workmanship and materials not known at the time of purchase and not discovered by the purchaser or anyone on behalf of the purchaser for a period of two years (730 days) from the date of original purchase.ĮSCO warrants to its customers that casted portions of the Product(s) will not fail as a direct result of and caused solely due to defects in workmanship and materials not known at the time of purchase and not discovered by the purchaser or anyone on behalf of the purchaser for a period of 3 years (1095 days) from the date of original purchase.Probably will get a ration of you know what about this but I'm going to say it anyway! Certain Products(s) contain restrictions to this limited lifetime warranty, additional warranties, or different warranty periods. Pressure Washers & Water Recovery Systems.Oil Drains, Funnels, Crushers, & Storage.

Alignment Systems, ADAS Systems & Accessories.

0 kommentar(er)

0 kommentar(er)